The G71 turning cycle is a roughing cycle used on CNC lathes to remove large amounts of material efficiently. It allows you to define a roughing path that the machine will follow, making multiple passes to achieve the desired shape. Here’s a breakdown of the G71 cycle and an example program:

G71 Cycle Format

The G71 cycle typically consists of two lines of code:

- First Line: G71 U(depth of cut) R(retract amount);

- Second Line: G71 P(start line) Q(end line) U(finish allowance in X) W(finish allowance in Z) F(feed rate);

Example Program

Here’s an example of a G71 roughing cycle program:

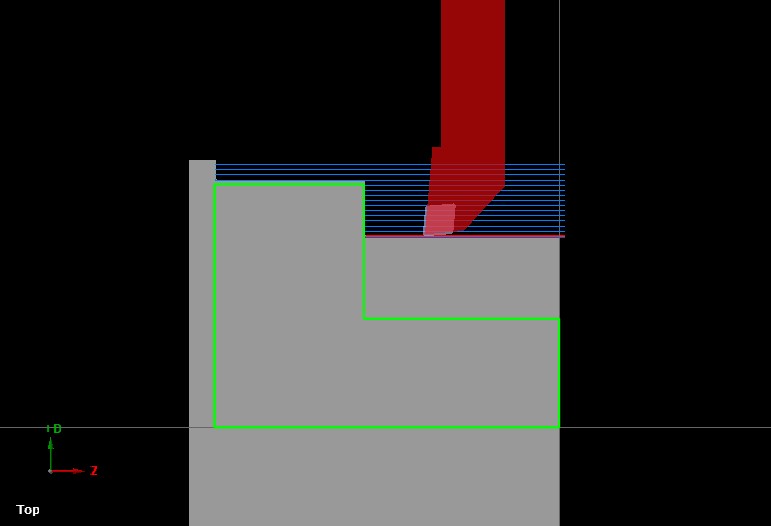

N10 G71 U1.0 R1.0; (First line: 1.0mm depth of cut, 1.0mm retract)

N20 G71 P100 Q200 U0.2 W0.05 F0.2; (Second line: start at N100, end at N200, 0.2mm finish allowance in X, 0.05mm in Z, 0.2mm/rev feed rate)

N100 G00 X19.0; (Move to start position)

N110 G01 G42 Z0.0 F0.2; (Linear feed, tool nose radius compensation on, move to front of part)

N120 X20.0 Z-0.5; (Cut to X20.0, Z-0.5)

N130 Z-20.0; (Move to Z-20.0)

N140 X40.0 Z-30.0; (Cut to X40.0, Z-30.0)

N150 Z-65.0 R5.0; (Move to Z-65.0 with 5.0mm radius)

N160 X60.0; (Cut to X60.0)

N200 G40 X70.0 Z5.0 F200; (End of subroutine, tool nose radius compensation off, move to safe position)

Explanation

- First Line (N10): Specifies the depth of cut (1.0mm) and retract amount (1.0mm).

- Second Line (N20): Defines the start (N100) and end (N200) of the subroutine, finish allowances (0.2mm in X, 0.05mm in Z), and feed rate (0.2mm/rev).

- Subroutine (N100 to N200): Contains the profile of the part to be machined. The tool moves to the start position, follows the defined path, and then retracts to a safe position.

This example should give you a good starting point for using the G71 turning cycle in your CNC programs. If you have any specific questions or need further details, feel free to ask!