The G74 cycle is used for face grooving or peck drilling in CNC machining, particularly with lathes. It allows for efficient removal of material by making multiple passes at incremental depths. Here’s a basic rundown of how to use the G74 cycle for face grooving:

G74 Cycle Overview

- G74: This command tells the CNC machine to execute a peck drilling or face grooving cycle.

- Parameters: You’ll need to set several parameters, such as the feed rate, depth of cut, and position coordinates.

Example of G74 Usage

N10 G50 S2000 T0100

N20 G96 S80 M03

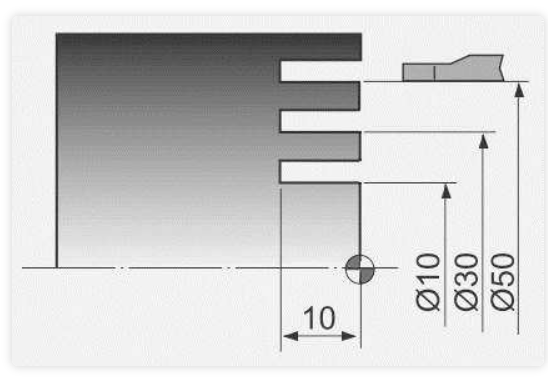

N30 G00 X50.0 Z1.0 T0101

N40 G74 R1.0

N50 G74 X10.0 Z-10.0 P10000 Q3000 F0.1

N60 G00 X200.0 Z200.0 T0100

N70 M30Explanation of the Parameters

- X and Z Coordinates: Defines the start point and depth of the groove.

- R: Retract height after each peck.

- P: Swift value in x axis

- Q: Depth of each peck in z axis

- F: Feed Rate

Considerations

- Tool Type: Ensure you’re using the correct tool for grooving.

- Material: Adjust feed rates and speeds based on the material being machined.

- Tool Wear: Monitor tool wear, as it can affect the quality of the groove.